Inventory management has traditionally been held together with spreadsheets, paper logs, and software that was built for a different decade. Teams rely on manual checks, copy-paste updates, and email chains to track what’s coming in, what’s going out, and what’s about to run out.

It’s not the most fun system to manage.

The systems are scattered, the data is out of sync, and even basic questions like “do we have enough stock to cover next month?” can take hours to answer. And when stock levels are off, everything from order fulfillment to financial reporting starts to unravel.

AI is a way to make inventory management easier. AI tools, especially specialized AI agents, can cut manual errors, save hours of repetitive work, and spot stock and supply chain patterns your team can act on before they turn into problems.

How companies use AI in their operations varies. According to the 2025 State of AI in operations report from Glide, 40% of small businesses use AI for efficiency, while 27% of enterprises say their priority is better insights and smarter decision-making. When it comes to inventory management, using AI can help you achieve both.

This guide looks at how to use AI for inventory management to replace scattered systems and second-guessing with data your team can trust.

type: embedded-entry-inline id: 7bf5vifJ7Fg1nlolNQsex5

1. Perform better demand forecasting with less manual effort

AI cuts down on the time and effort it takes to forecast demand, pulling in and analyzing data from different sources to generate forecasts that are more accurate and easier to act on.

That kind of clarity is exactly what many businesses are looking for. More accurate forecasts mean better insights and smarter decision-making—the very reason 27% of enterprises say they’re adopting AI.

When forecasting demand manually, you might look at historical data, track current promotions, factor in seasonal swings, or get input from sales and suppliers. Even if you’re combining multiple methods, you’re still stitching together data from different sources and hoping nothing gets missed. It takes time and resources that many businesses just don’t have.

Machine learning algorithms can pull in and analyze all of these inputs in a fraction of the time. With tools like Glide, you can connect your inventory, sales, and supply chain systems directly to an AI model to give it the complete picture of your data without manual data entry. Your team can make better decisions based on reliable forecasts and spend less time wrangling spreadsheets or chasing down updates from different teams.

Yogurt giant Danone, which works with perishable products and risks spoilage if forecasts are off, is a clear example of how AI-powered demand forecasting delivers results. With the help of AI, the company achieved a 20% reduction in forecast error and increased forecast accuracy to 92%.

2. Adjust inventory in response to demand shifts

AI-powered inventory management systems can adjust to real-time sales and supply data to help avoid overstock and stockouts with flexibility.

Manual inventory management can’t adapt fast enough to changing conditions like a shift in market trends or a spike in sales. The result is often excess stock tying up capital and driving up insurance premiums or emergency reorders that cut into margins. AI systems help you respond before that happens and keep products available where they’re needed most.

Instead of setting static reorder points for every SKU, you can use an AI inventory management agent to monitor sales patterns and delivery schedules. The AI system flags when stock is likely to dip below target or pile up, then recommends updated reorder points or quantities. Your team can review these suggestions and approve, reject, or modify a reorder.

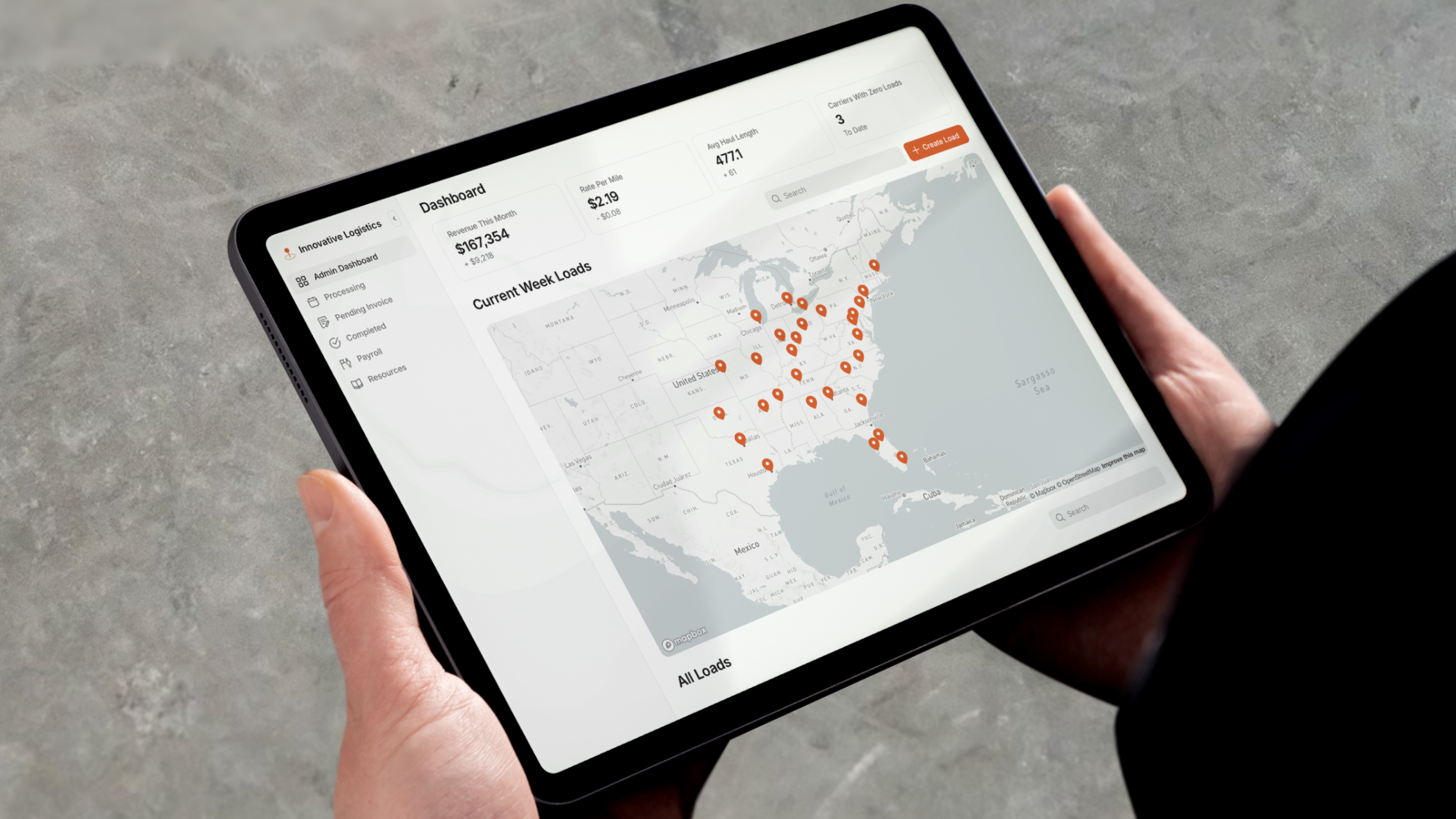

An AI agent can also adjust stock levels between your business’s different stores or warehouses instead of triggering a reorder alert each time. The system can track stock across all sites and flag potential imbalances. If it predicts that one store will have more inventory than it needs while another runs low, it can recommend moving stock between locations before a shortage becomes a problem.

That flexibility helps you respond to demand shifts quickly and adjust before a stockout or overstock becomes a bigger issue. You can be proactive instead of reactive, so your warehouse or retail staff isn’t wasting time making phone calls to check where more stock is available and manually coordinating deliveries.

3. Make delivery routes more efficient

Inventory management doesn’t end at the warehouse. AI helps plan faster, more fuel-efficient routes to optimize how stock gets to its destination, keeping shipments on schedule and operations running smoothly.

When your team plans delivery routes manually, it’s hard to account for what's happening on the ground. Traffic jams, accidents, road construction projects, or poor weather conditions can all cause delivery delays.

An inventory management AI agent can pull in real-time data like traffic patterns, road conditions, and weather, then adjust routes to avoid delays and reduce fuel consumption. Your team doesn’t need to make new plans every time a road closes or a driver gets stuck in a gridlock. The AI agent recommends the next best option, and your team approves or modifies it based on what’s happening on the ground. The result is faster deliveries and more efficient use of vehicles and drivers.

Efficiency is the most common reason companies reported for adopting AI, and this is especially true for smaller businesses and industries like manufacturing, logistics, and transportation.

Companies like DHL and UPS already use AI-powered systems to find the optimal delivery route, shaving time off deliveries and cutting fuel consumption at scale. Smaller teams can also use AI to stretch limited resources further—moving stock faster using fewer vehicles, less fuel, and less time.

4. Improve inventory accuracy with real-time tracking

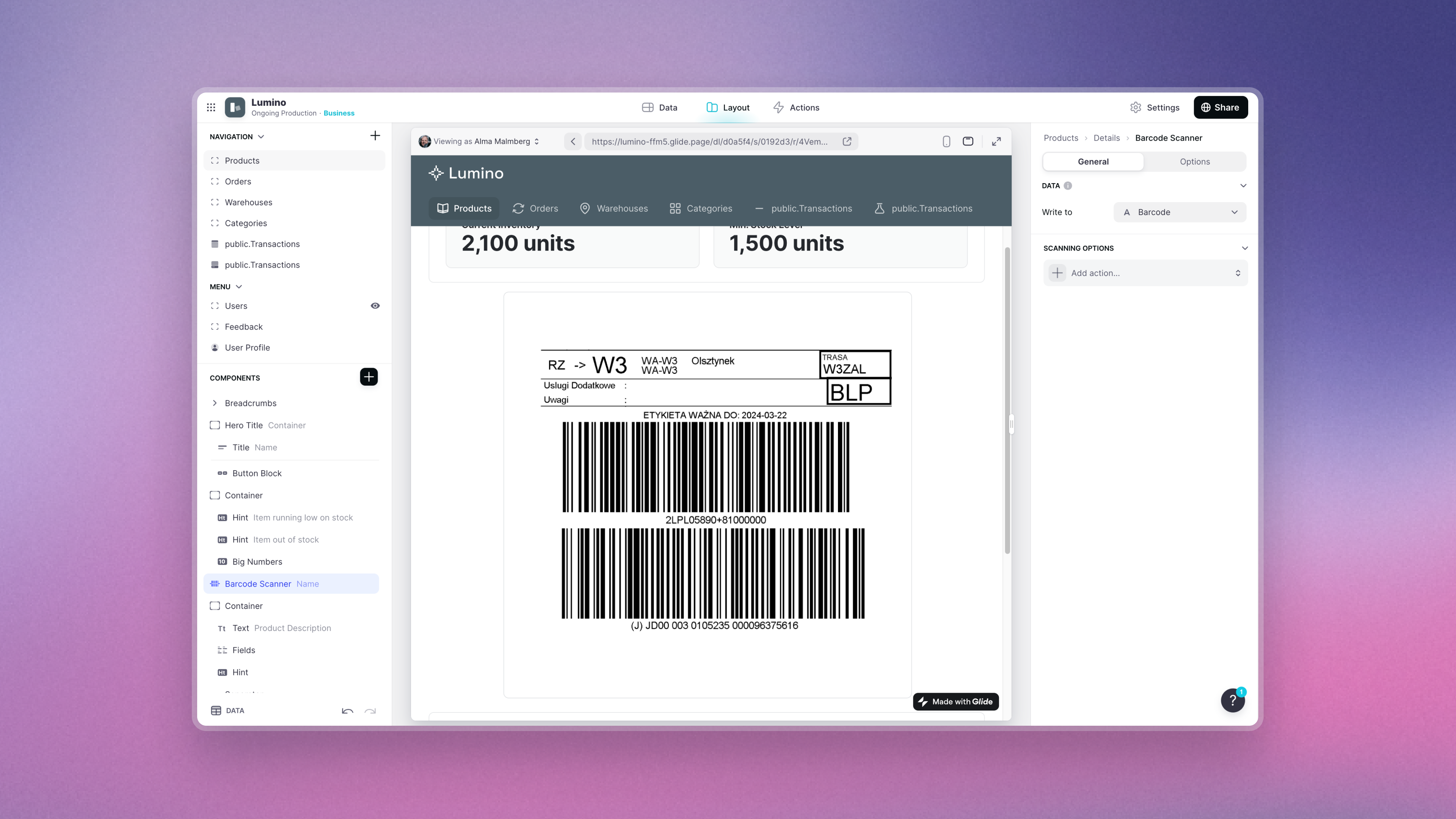

AI-powered inventory management systems give your team a real-time, accurate view of what’s in stock across warehouses, store shelves, and even goods in transit.

When different systems don’t talk to each other, it’s easy for inventory data to get out of sync. AI helps by connecting your inventory management software to tools like:

Barcode scanners to log item movement when products are received, counted, or sold, such as scanning shipments of groceries at receiving docks in a supermarket.

RFID tags to track inventory location and quantity as items move location, such as monitoring apparel from the backroom to the sales floor in retail.

IoT shelf sensors to detect when the weight of items on a shelf changes, like the movement of feed bags in an agricultural warehouse.

Sales or order systems to update inventory records when a transaction occurs, or items are used up in a production batch.

AI analyzes this data in real time and can spot mismatches between what’s recorded and what’s actually there. For example, it might flag that an item was logged as shipped when it’s still on the shelf or that the stock count is off after a delivery. Over time, AI can learn from these discrepancies and detect patterns in data errors for you to act on.

You can also build live dashboards for your team to make periodic checks. Automated alerts can notify a manager if inventory drops unexpectedly or if a supply is marked as used without being scanned out. Your team will spend less time on manual stock checks and investigating where something went missing.

Advanced chemistry company CarboNet used a custom Glide app to automate inventory tracking across warehouses. With their data now accurate and always up to date, the team saved dozens of hours each week that would otherwise be spent manually tracking and verifying inventory accuracy.

5. Protect the balance sheet with verified inventory data

Inventory errors aren’t just operational issues—they can end up on your financial statements. AI helps keep your balance sheet accurate by catching inventory discrepancies that inflate asset values or distort financial reports.

Inventory items that are stolen, scrapped, spoiled, or miscounted but never updated in your system stay in your financial records. And when your balance sheet shows $500,000 in inventory but your warehouse actually contains $425,000, you’re making business decisions based on stock that doesn’t exist.

AI-powered inventory systems help surface these red flags in real time: a delivery marked as received but never scanned into stock, or ongoing mismatches between what the system says is there and what your team finds during spot checks. Instead of waiting for quarterly reviews or year-end audits, your finance team can catch these issues early and keep financial records aligned with actual stock levels.

Here’s how your finance team can stay on top of an inventory-financials mismatch.

Real time alerts: When the AI detects a significant mismatch between recorded and actual inventory, it immediately sends an alert to the team. For example, if a large shipment is logged as received but not scanned into inventory within 24 hours, your finance manager gets a notification to investigate.

Live dashboards: You can build customized inventory management dashboards that give you real time access to data. These dashboards give your team a visual display of current inventory levels, highlight discrepancies, and track trends over time.

Automated reconciliation reports: The AI system generates weekly—or even daily—reconciliation reports that compare recorded inventory against actual stock levels, factoring in sales, receipts, and known losses. These reports flag items with persistent discrepancies, helping your team identify systemic issues rather than one-off errors.

These tools give your finance team real time visibility to act on discrepancies in a way that managing inventory manually just can't.

6. Write product descriptions faster and more consistently

Whether you’re selling directly to consumers or supplying retailers, AI helps you generate clear, accurate product descriptions as soon as they’re added to the system.

When your team is adding dozens (or hundreds) of new SKUs each week, it’s easy to fall behind on descriptions. Many businesses end up reusing generic copy, skipping important details, or delaying product uploads until someone has time to write them. Manual product descriptions slow down sales and hurt search visibility.

Generative AI features in your inventory management system make it easier to create consistent, accurate product copy in seconds. You can instruct the AI to use the product’s photo, name, or specifications, and the AI fills in the rest—color, material, dimensions, use cases—based on the type of product it's describing. You choose the format and tone, whether that’s technical specs or conversational copy.

Your ecommerce company can list new products faster by using AI to generate descriptions so you’re not delaying sales while waiting on content. If you’re a wholesale supplier, AI descriptions make it easier for retailers to understand your catalog, spot the differences between SKUs, and choose the right products for their shelves.

Using AI to write product descriptions saves your team time and makes it easier to scale your listings while maintaining consistency. Whether you’re launching a new product line or updating old listings, your team can create polished descriptions without waiting on a copywriter or digging through spreadsheets.

7. Help field sales teams sell what’s actually in stock

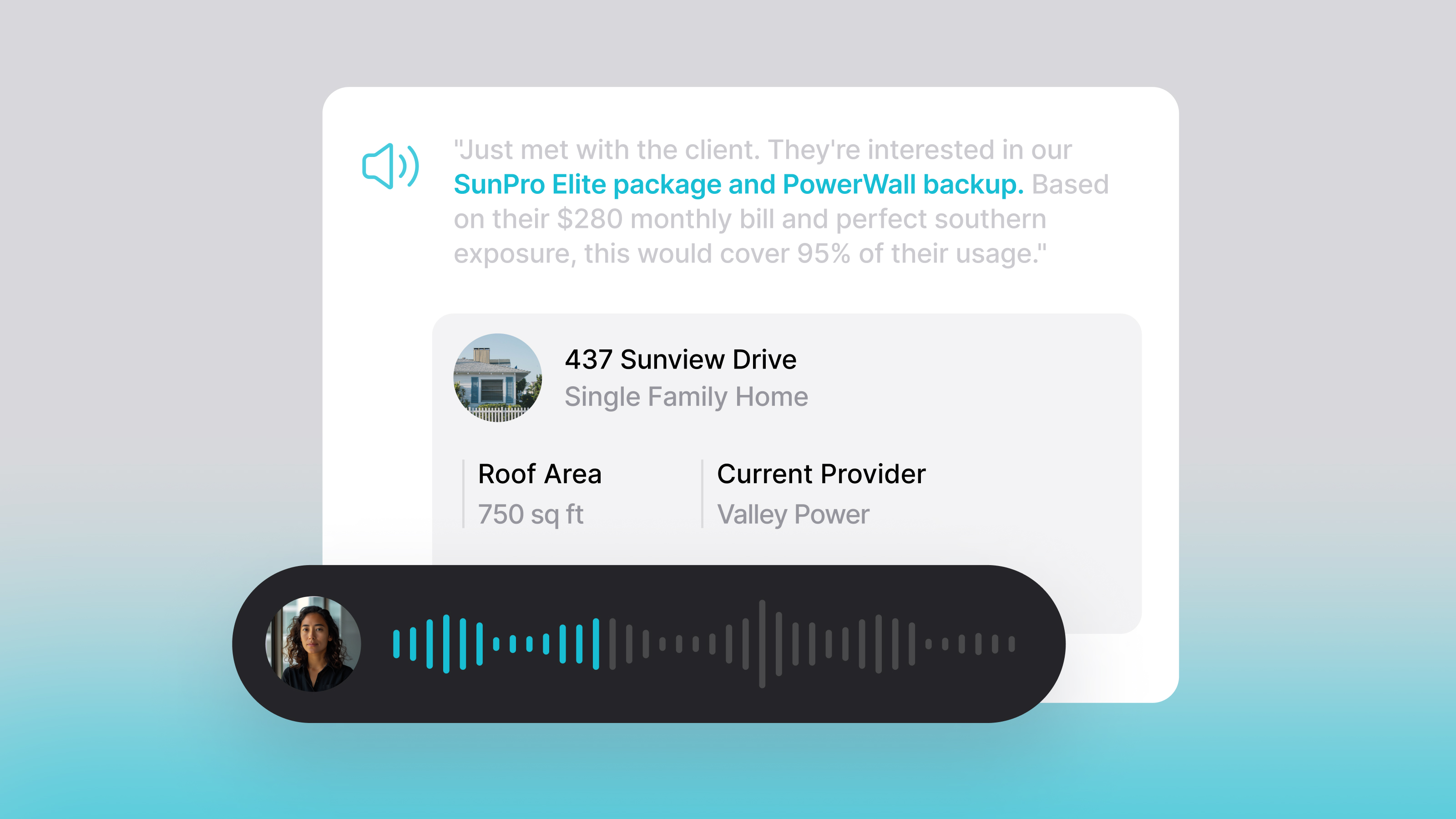

Sales move faster when reps have real-time inventory data at their fingertips. Connecting an AI sales agent to your inventory management system gives your sales reps direct access to what’s in stock so they can close deals without guesswork or delays.

When your sales reps are meeting with customers, they need to know exactly what’s in stock and when it can be delivered. Without real-time inventory data, they’re selling in the dark. They might promise products that aren’t available, miss opportunities to offer alternatives that are in stock or delay deals while they email the warehouse team for manual inventory checks.

With your inventory management system connected to an AI sales agent, reps can pull up real-time stock data on their phones. If a product is available, they can strike a deal right away. If an item is low or out of stock, they’ll see it immediately and can offer an alternative before the customer walks away. No guessing, no double-checking, no selling stock that doesn’t exist—just accurate inventory data when and where your sales team needs it.

8. Make order fulfillment faster and more reliable

Fulfilling orders gets faster when your inventory system can check stock and flag issues the moment an order comes in. Connecting your inventory and order systems with AI eliminates manual double checks and prevents last-minute surprises that slow down your fulfillment process.

For both direct-to-customer and B2B businesses, how quickly and accurately you fulfill orders directly impacts customer satisfaction. When fulfillment teams have to dig through spreadsheets or wait for inventory updates from other departments, it delays order processing and increases the chances of something getting missed. Plus, your teams can’t always take external factors into account, like delays at security checkpoints, unexpected weather events that slow down shipping, or delivery vehicle breakdowns.

When inventory and order systems are connected, AI flags anything that might delay or disrupt an order so your team can fix the issue before the sale goes through. For example, in the food and beverage industry, AI can flag when items may expire before they reach the customer so the team can use fresher stock instead. In wholesale, AI flags when factors like truck shortages mean an order might not be delivered on time, even if stock is available. This gives your team time to adjust the shipment or give the customer a heads-up.

By removing the manual effort of matching orders against inventory—and accounting for things that humans might overlook or can’t predict—you make the entire order fulfillment process faster and more reliable.

9. Speed up inspections without compromising on quality

Product quality inspections might not be the first thing that comes to mind when you think of AI—but they’re one of the best fits for its use. AI inspections agents can inspect hundreds of products in minutes, flag defects with consistent criteria, and generate reports your team can act on immediately.

Traditional quality control requires your staff to physically examine each product, follow detailed checklists, and make subjective judgments about what constitutes a defect. This process is not only time-consuming but inconsistent—what one inspector flags as defective, another might pass as acceptable. And as your team gets tired toward the end of a shift, inspection accuracy naturally declines.

An AI inspections agent cuts down on the time and effort it takes to complete product quality inspections. When a product arrives at your warehouse, your receiving team can snap photos from multiple angles and upload them to your AI inspections agent along with any voice notes.

Within seconds, the AI system identifies defects in the product—things like scratches, dents, color inconsistencies, or missing components that might not be immediately obvious. Your team can quickly review flagged items and decide whether to approve, reject, or escalate the issue. You get a shareable report you can review on the spot, send to a supplier, or attach to an internal ticket.

The system examines each item against the criteria you set, and it applies the same rigorous criteria to the first product and the thousandth. That means consistency across every inspection, with no need to second-guess how different team members might interpret a checklist.

10. Track spoilage risk before it becomes a problem

When products with limited shelf life sit in your warehouse or stockroom, every day counts. AI helps you act on spoilage risks before expired or compromised stock affects customers, compliance, or your bottom line.

Traditional tracking methods like spreadsheet checks leave too much room for error. By the time someone realizes a product is about to expire, it might be too late to do anything but throw it away.

AI systems track production dates, batch numbers, and storage duration for every item and flag products that are approaching expiration dates or exceeding shelf-life thresholds. Instead of discovering expired products during manual inventory, you get alerts while there’s still time to move the merchandise.

The benefits multiply when you connect environmental sensors to your AI inventory management agent. Temperature spikes in cold storage, humidity fluctuations in sensitive product areas, or other storage issues like equipment failures trigger immediate alerts to your warehouse team. Your staff can immediately move at-risk items, adjust storage conditions, or notify a supplier if there’s an equipment issue.

For food distributors, pharmaceutical companies, or any business that uses perishable products, this visibility can dramatically reduce waste, eliminate write-offs, and protect your reputation.

11. Make faster, smarter decisions from your data

Enterprise companies say their top reason for adopting AI is better insights and smarter decision-making. AI-powered inventory management systems analyze your scattered data, identify patterns, and help your team make better decisions without hours of manual analysis.

With 61% of companies using AI for business intelligence of this kind—and half describing its impact as “transformational”—it’s clear more teams are turning to AI to make sense of complex data. This shift is happening for a reason. When data lives in different systems, teams waste time pulling reports, switching between spreadsheets, and trying to understand what’s going on with stock, suppliers, or fulfillment.

AI systems pull together data from your inventory, sales, and supply chain tools, then analyze it and highlight trends, risks, or issues that need attention. You can build role-based dashboards in your inventory management app so ops sees stock movement, finance sees write-offs, and warehouse teams see reorders and delays. Your team can ask questions in plain language—like “What’s causing this quarter’s spike in write-offs?”—and get context-aware answers backed by real-time and historical data.

It’s not just enterprise teams that benefit. Small and midsize businesses can also use AI to improve decision-making. Agricultural advisory company Aarde built a custom Glide app to track crop forecasts, planting and harvesting schedules, and share team updates in one place. This gave them more accurate data to make decisions, resulting in a 5–10% increase in crop yield and over $100,000 a year in saved software and staffing costs.

With AI handling the heavy lifting, your team can stop chasing data and spend more time making decisions that benefit every aspect of the business.

12. Drive profitability with better stock control

AI-powered inventory systems improve how your business runs and how it earns.

Most of the benefits of AI we’ve covered—faster fulfillment, smarter stock control, fewer errors—focus on operational efficiency. But they also contribute to revenue growth—the third most common reason companies adopt AI, and the top reason in retail.

Here’s how better stock control with AI contributes to profitability.

Less money lost on overstock or stockouts: Accurate demand forecasting helps you order the right amount so you’re not spending on inventory that sits unsold or missing revenue from products that run out.

Lower cost of operations: AI handles tasks like inspections and inventory tracking, reducing the labor hours needed to run your business and the payroll costs that go with them.

Smarter delivery routes: AI suggests the most efficient routes based on real-time traffic, road closures, or delivery windows so trucks are on the road for less time and you spend less on fuel.

Fewer spoilage losses: You can catch and act on expiry risks early so inventory is sold in time or rerouted elsewhere, not written off.

More closed deals: With access to accurate inventory data, your field sales teams quote with confidence, offer in-stock alternatives, and move faster, leading to higher conversion rates and average order values.

More accurate financials: AI flags discrepancies between system and shelf data early, so your finance team isn’t making decisions based on inflated asset values or missing write-offs until audit time.

Demand planning company Shelf Engine is a clear example of how smarter inventory planning can directly increase profitability. Shelf Engine used AI-powered demand forecasting to help a grocery chain reduce waste, save labor hours, and improve margins—adding $40 million in incremental profit in one year.

type: embedded-entry-inline id: 6c7r4ystDhcbm3FyOAmmZQ

Unify your inventory management system with AI

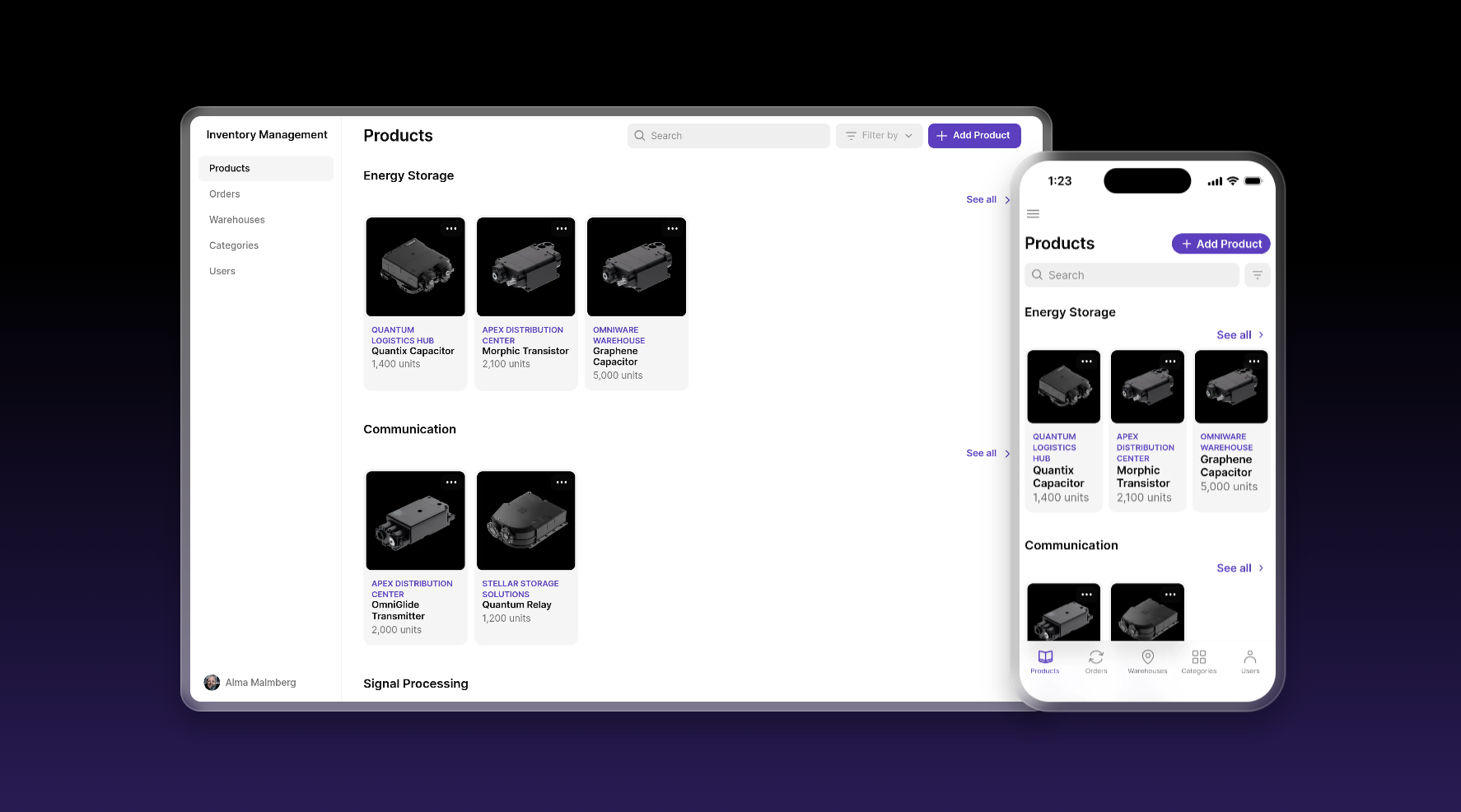

Building an AI-powered inventory management system starts with connecting your data, tools, and team workflows in one place. Start by building an inventory management app in Glide. Then, add AI capabilities that support your team's unique way of working.

Glide’s managed AI setup handles model selection automatically, so you don’t have to choose the right model or configure anything manually and the no code builder allows you to craft your inventory management software to your exact specifications.

There are different ways to build and connect AI to your app, depending on your time frame and technical comfort level. Whether you start with a template, build from scratch, work with a Glide Expert, or reach out to the Glide team, you choose the method that works best for you.

However you begin, the goal is the same: an inventory management system that uses AI to support your team’s real workflows, whatever your size or setup.